Our PrintS

We aim for the best, experience one of the finest custom t-shirt printing technology available in Malaysia. Our cutting-edge printing solutions including silk screen, heat press, sublimation, and others help you to enhance corporate apparel branding while delivering unmatched quality. We offer unique customizations to craft impactful products catering to indie brands to large business.

Non textured prints

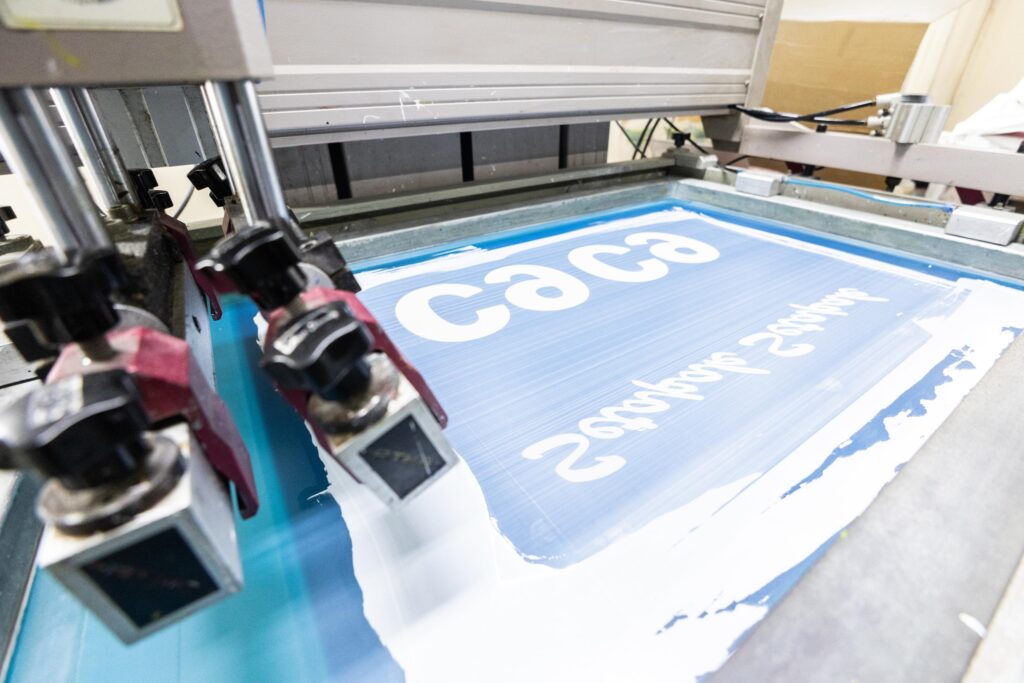

Screen printing is the go to choice for vibrant & durable t-shirt designs. Perfect for all purpose bulk orders, corporate apparel, and custom brands.

Screen printing is the go to choice for vibrant & durable t-shirt designs. Perfect for all purpose bulk orders, corporate apparel, and custom brands.

Heat and pressure applied on transfer paper to enable fast personalized designs and versatile on-demand printing.

Heat and pressure applied on transfer paper to enable fast personalized designs and versatile on-demand printing.

Inks are infused into the fabric using heat, creating vibrant, long-lasting prints that won’t crack or fade over time.

Inks are infused into the fabric using heat, creating vibrant, long-lasting prints that won’t crack or fade over time.

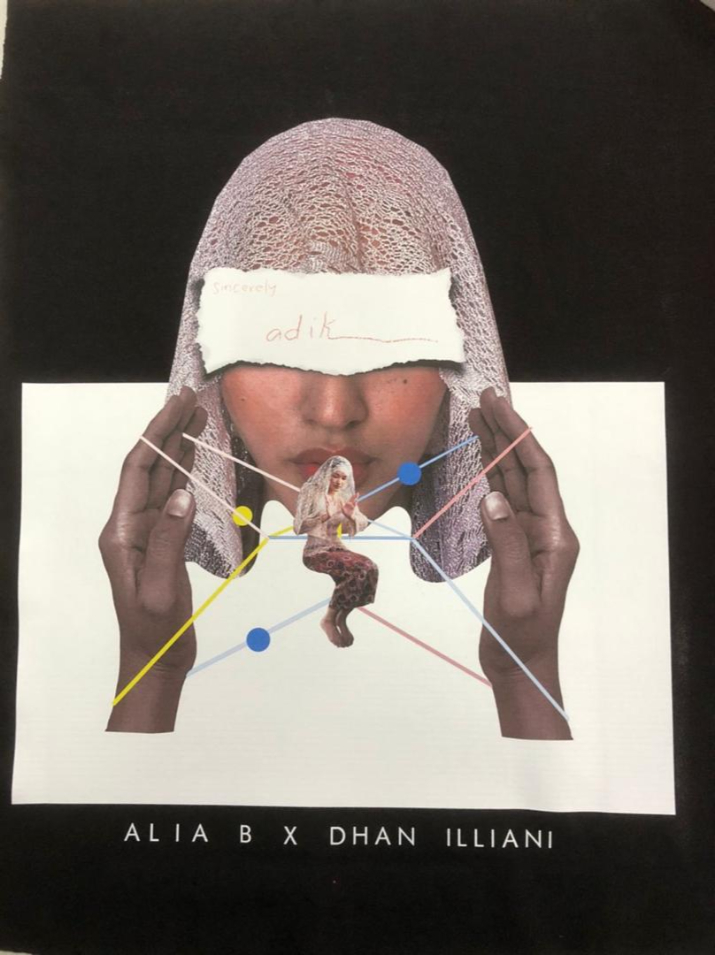

Ink is sprayed directly onto fabric, allowing for soft feel breathable prints with no heavy ink feel.

Ink is sprayed directly onto fabric, allowing for soft feel breathable prints with no heavy ink feel.

Textured prints

Threads stitched directly onto fabric, creating a durable and textured look that won’t fade and crack.

Threads stitched directly onto fabric, creating a durable and textured look that won’t fade and crack.

Embossing creates a raised 3D effect by using heat and pressure to mold the design.

Embossing creates a raised 3D effect by using heat and pressure to mold the design.

Inks layered repetitively to create a raised, 3D effect with sharp edges and a rubbery texture.

Inks layered repetitively to create a raised, 3D effect with sharp edges and a rubbery texture.

Specialty prints

Color changing print that responds to temperature changes.

Color changing print that responds to temperature changes.

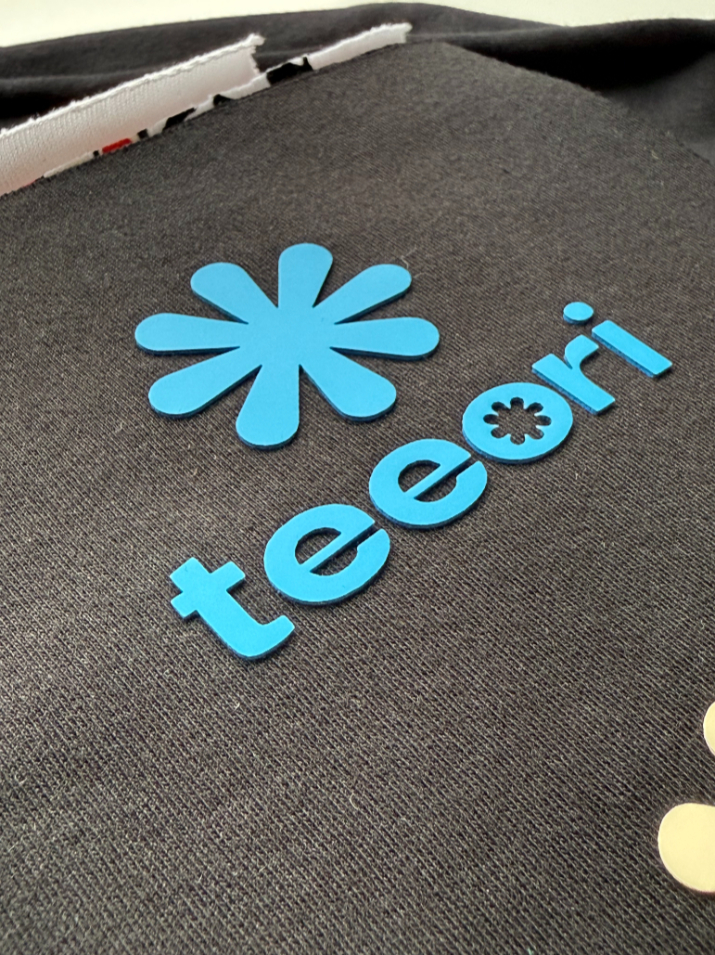

Rubbered texture providing an outlook of raised 3D effect. The material is waterproof, abrasion resistant, and durable.

Rubbered texture providing an outlook of raised 3D effect. The material is waterproof, abrasion resistant, and durable.

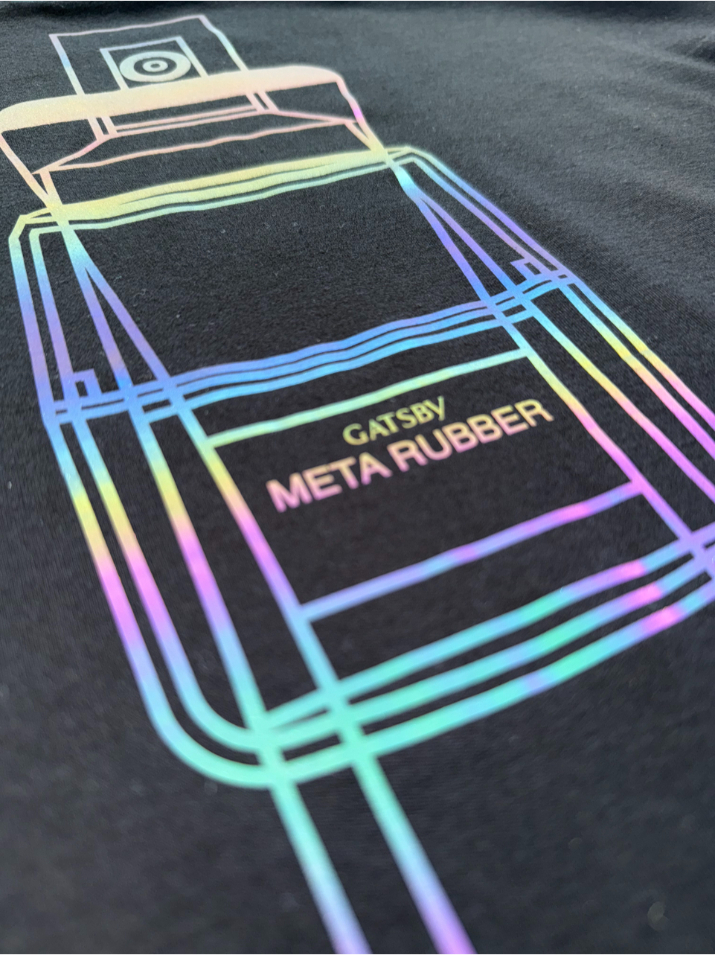

Light reactive material that shines under light, maximizing visibility and style.

Light reactive material that shines under light, maximizing visibility and style.

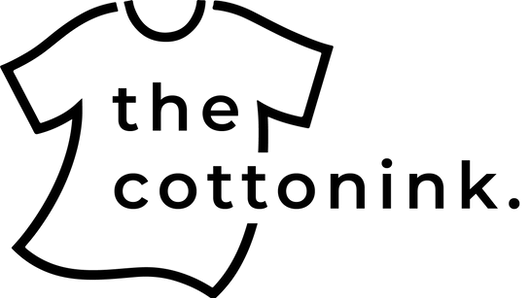

Passion for Prints

Machine vs Hand printing

We offer both hand & machine custom t shirt printing to match the varying need of our clients. Machine printing ensures cost-effective, high-volume production with consistent quality while Hand printing is perfect for lower volume designs with an artisanal touch. This flexibility lets us cater to both unique and large scale projects

Inks & etc

Whether it’s inks, embroidery, silicone, or specialty materials, we’re always exploring and experimenting with print materials from around the world to ensure our customers receive high quality apparel printing.

Ink: We carry plastisol, water based, glow in the dark, puff, metallic ink that complements screen printing.

Other materials: Transfer paper, threads, silicone, glitter are also part of our stable for more variety.

Feeling experimental? Talk to us to explore more printing choices